To minimize movement, shrinkage and settling in the timbers over time, the company combines natural air-drying and kiln-drying measures in the manufacturing of every Honest Abe timber.

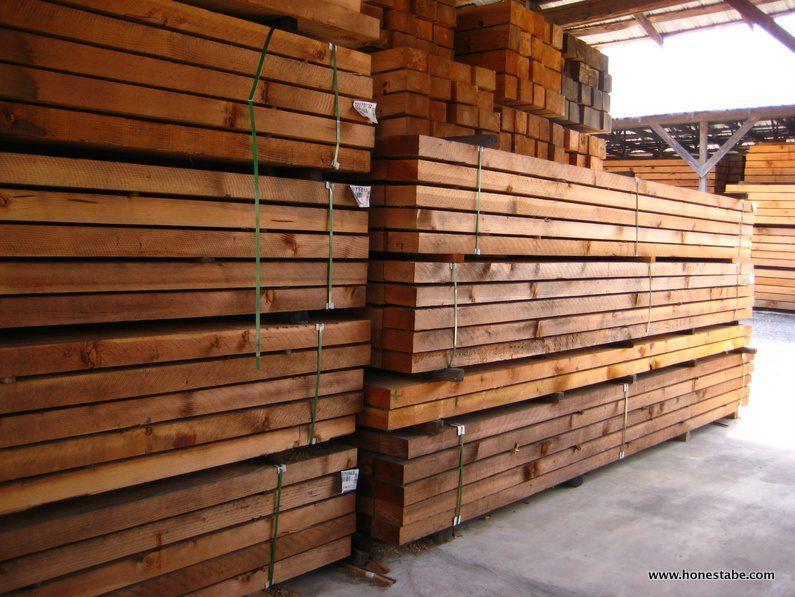

Every piece of wood used is dried in kilns on site, then stored under cover until it becomes part of an Honest Abe Log Home. The drying process produces a more stable log and tighter joints for the construction of your log home or building. Because they don’t believe in rushing this process, Honest Abe averages a nine-month inventory of timbers, something many of the competitors can’t say.

The factory uses 3-D modeling and computer-driven equipment overseen by a team of dedicated craftsmen. Every log that goes into a home or building is cut to exact specifications for a perfect fit – a critical step when it comes to windows, doors and corner notches.

Honest Abe knows how to plan for shipping.

For every individual building, the pre-cut logs are numbered, wrapped and neatly bundled for protection during delivery. You can know and trust that each piece of your wood structure that comes from Honest Abe’s facility has been carefully produced, graded and packaged..